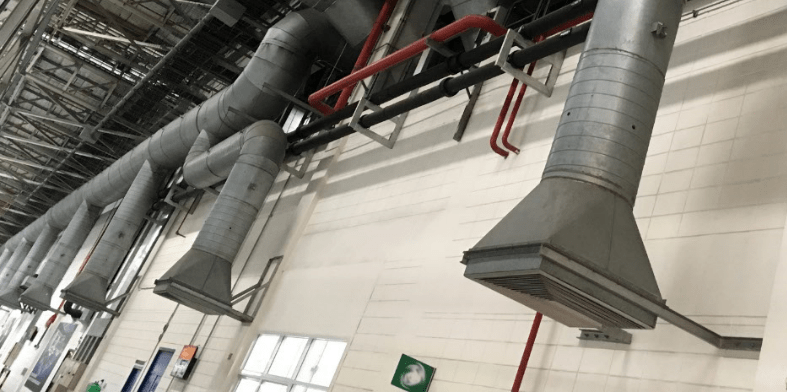

In any workplace where hazardous substances, dust, fumes, or vapors are present, maintaining a safe environment is not just a legal requirement—it is essential for the health and well-being of employees. One of the most effective ways to achieve this is through the use of LEV systems, or Local Exhaust Ventilation systems. These systems are designed to control and remove airborne contaminants, ensuring that workplaces remain compliant with safety standards and regulations.

Understanding LEV Systems

LEV systems are specialized ventilation systems that capture contaminants at or near their source before they can spread into the workplace air. Unlike general ventilation, which dilutes contaminants throughout a space, LEV systems target the specific area where harmful substances are generated. This focused approach ensures a higher level of safety for employees while minimizing exposure to hazardous materials. LEV systems can be installed in factories, laboratories, workshops, and any other environment where airborne risks are present.

The Role of LEV Systems in Workplace Safety

Workplace safety regulations often mandate strict control of exposure to harmful substances. LEV systems play a crucial role in meeting these requirements by effectively removing airborne contaminants. By doing so, they help prevent occupational illnesses and reduce the risk of long-term health problems caused by inhaling dust, fumes, or chemicals. LEV systems not only protect employees but also demonstrate a company’s commitment to maintaining a safe and compliant workplace environment.

Ensuring Compliance with Legal Standards

Many countries have specific regulations regarding workplace exposure limits for various substances. LEV systems help businesses meet these standards by consistently controlling and monitoring the levels of contaminants in the air. Regular inspection and maintenance of LEV systems are often required by law to ensure they remain effective. By implementing these systems and maintaining them properly, companies can avoid fines, legal complications, and potential shutdowns while fostering a safer work culture.

Benefits Beyond Compliance

While the primary goal of LEV systems is to maintain compliance with safety standards, their benefits extend further. Effective LEV systems can improve overall air quality, reduce odors, and create a more comfortable working environment. Employees who work in cleaner, safer conditions are often more productive and motivated. Furthermore, the presence of LEV systems can enhance a company’s reputation by showing that it prioritizes health, safety, and environmental responsibility.

Key Components of Effective LEV Systems

An effective LEV system includes several critical components, such as hoods, ductwork, air cleaners, and fans. Each component works together to capture and remove contaminants efficiently. Hoods are placed close to the source of emission, ductwork transports contaminants away, air cleaners filter the harmful substances, and fans maintain airflow throughout the system. Proper design and installation are essential to ensure the system works correctly and complies with safety standards.

Monitoring and Maintenance

Even the most well-designed LEV systems require regular monitoring and maintenance to remain effective. Routine checks can identify any blockages, leaks, or malfunctions that could reduce the system’s performance. Employers should also keep records of inspections and maintenance activities, as these documents may be necessary to demonstrate compliance during regulatory audits. Consistent maintenance ensures that LEV systems continue to provide the protection needed to maintain workplace safety.

Training and Awareness

Installing an LEV system alone is not enough. Employees must understand how to use and work safely around these systems. Training staff on the correct use, potential hazards, and importance of reporting issues ensures that LEV systems function optimally. Awareness programs also help employees recognize the benefits of LEV systems and encourage them to follow safety protocols, further reinforcing compliance with workplace safety standards.

Conclusion

LEV systems are an essential part of any workplace safety strategy, providing targeted control of airborne contaminants and helping organizations meet strict regulatory requirements. By understanding their importance, maintaining the systems properly, and educating employees on their use, businesses can create safer, healthier environments while avoiding legal penalties. Ultimately, investing in LEV systems is an investment in both compliance and the well-being of everyone in the workplace.