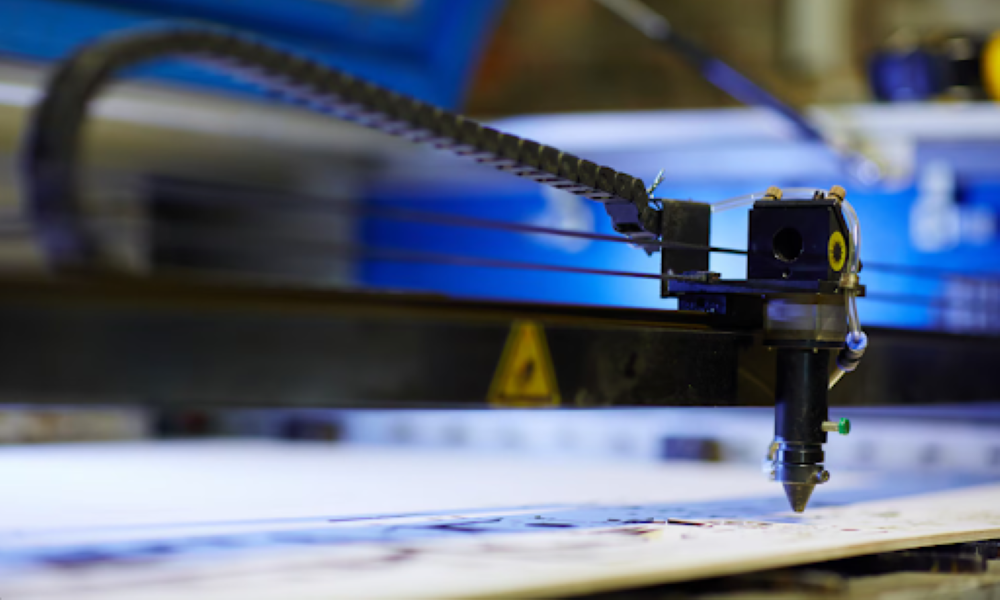

Manufacturing isn’t cheap, especially when you’re working with metal, precise parts, and tight deadlines. Every mistake, delay, or extra step adds up, leaving businesses frustrated and wallets lighter. That’s where modern technology steps in to save the day. Fiber laser machines are one of the tools that help factories cut costs without cutting corners.

They slice through metal and other materials with speed, accuracy, and minimal waste. If you’re curious about how investing in the right equipment can actually save money, let’s take a simple look at how fiber laser machines make production more efficient and budget-friendly.

1. Faster Production Speeds

Time is money, and fiber laser machines are fast. Unlike traditional cutting methods, which can take longer and need multiple steps, fiber lasers cut precisely in one go. This means products move from raw material to finished parts much quicker.

Faster production reduces labor costs and increases output, so companies can produce more without hiring extra staff. It’s like replacing a hand saw with a high-tech lightsaber where everything gets done in a fraction of the time.

2. Reduced Material Waste

Every scrap of material you throw away costs money. Fiber laser machines are incredibly precise, producing clean, accurate cuts that minimize leftover scraps. Less waste means fewer materials need to be purchased, and more pieces can come from the same sheet of metal. Over time, this efficiency can save a company thousands of dollars and make the production process more environmentally friendly.

3. Minimal Maintenance and Downtime

Older cutting machines often need frequent maintenance, and downtime can be expensive. Fiber optic laser systems are designed for long-term use with less upkeep. The machines are reliable, so production continues without unexpected interruptions.

Fewer breakdowns mean less money spent on repairs and less time lost, keeping the factory running smoothly. It’s like having a car that never needs oil changes and never gets a flat tire.

4. Reduced Labor Costs

Manual cutting and multiple-step processes require more workers. With fiber laser machines, one operator can handle tasks that might otherwise need several people. Automation and high-speed cutting reduce the need for extra hands while keeping accuracy high.

That doesn’t just save wages—it also reduces mistakes caused by human fatigue or inexperience. Less rework and fewer errors mean money stays in the company’s pocket.

5. Lower Energy Consumption

Energy costs add up fast, especially in heavy manufacturing. Fiber laser machines use less energy than older laser or cutting systems because the laser beam is more efficient.

Using less electricity while maintaining high performance means companies can reduce their utility bills without sacrificing production quality. It’s a small change that has a noticeable effect over time, especially for large-scale operations.

6. Better Quality, Less Rework

Mistakes cost money, whether it is damaged parts, scrap material, or slow production. Fiber laser machines create clean, precise cuts that reduce the need for rework. High-quality parts leave the machine ready for assembly or shipment, saving time and money down the line. Consistency in production also improves customer satisfaction, which can lead to repeat business and fewer complaints.